PVB e feletseng khalase laminated line tharollo

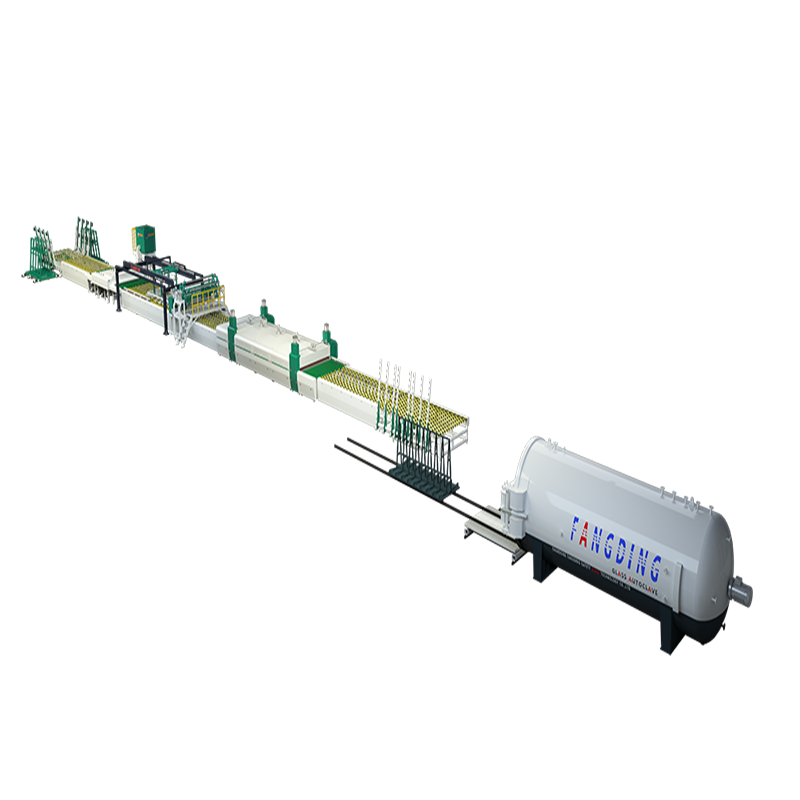

Tlhaloso ea Sehlahisoa

Re fana ka tharollo e feletseng ea lisebelisoa tsa khalase tsa laminated.Litlhaloso le litlhophiso ke tsa boikhethelo, re bolelle litlhoko tsa hau tse ikhethileng, 'me re tla u etsetsa tharollo e nepahetseng.

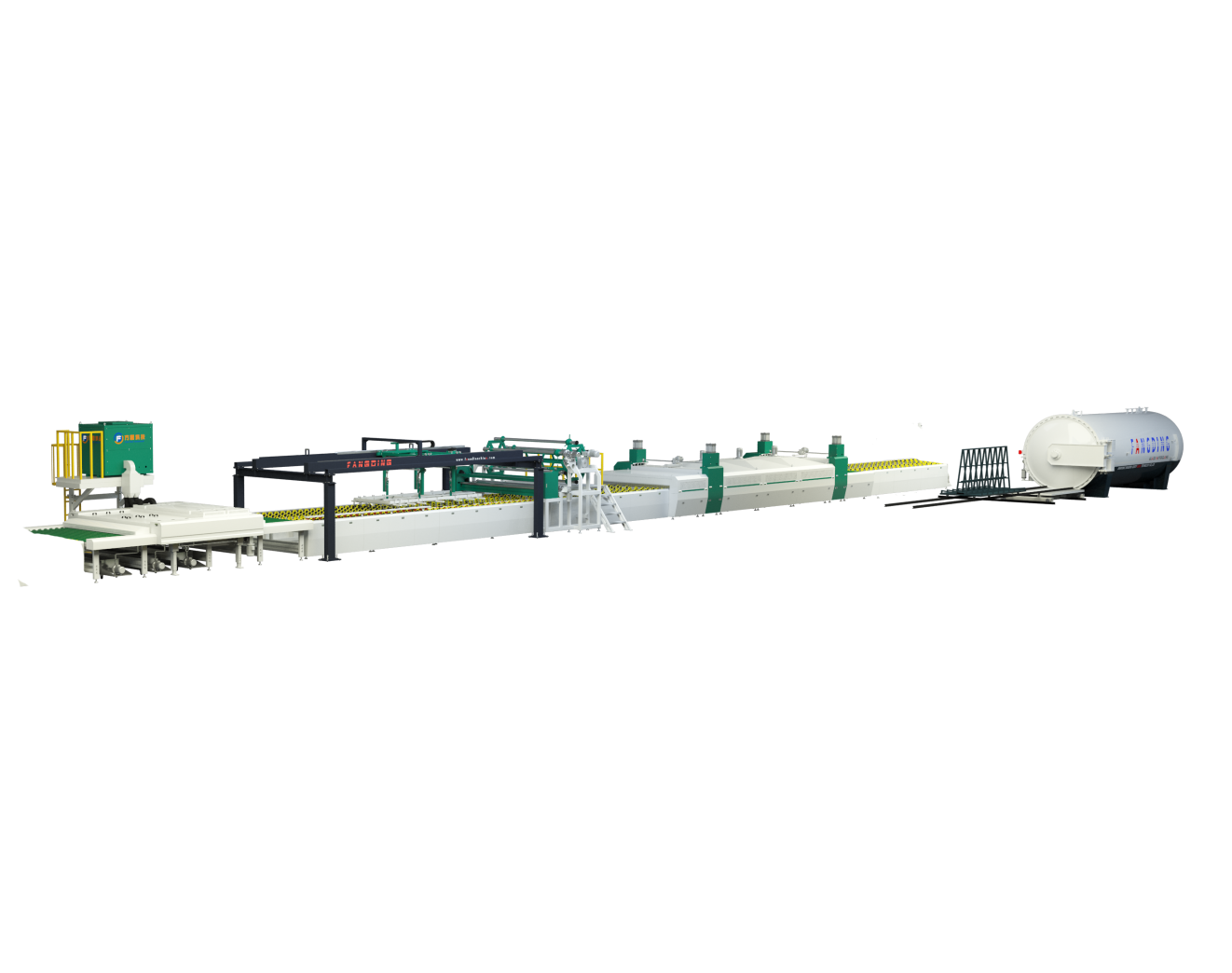

| Tlhahiso | PVB laminated glass production line |

| Moetso oa mochini | FD-L2500 |

| Matla a lekantsoeng | 540KW |

| Ho sebetsa boholo ba khalase | Max.boholo ba khalase: 2500X6000mm Min.glass boholo: 400mmx600mm |

| Botenya ba khalase | 4-60 limilimithara |

| Sebaka sa fatše | L*W: 63000mm×8000mm |

| Palo ea li-volts | 220-440V 50-60Hz 3-mohato AC |

| Nako ea ho sebetsa | 4-6h |

| Mocheso o sebetsang | 60-135ºC |

| Boima bo kahare | 50t |

| Sistimi ea ts'ebetso | Siemens PLC |

| Tlhahiso | 400-600 Sq.m/cycle |

Phallo ea Ts'ebetso

1. Khalase ea laminated e sephara

ho kenya letlapa le le leng la khalase → phetoho → Ho hloekisa le ho omisa→ ho kopanya → phetoho → futhumatsa pele le ho hatella pele → ho laolla letlapa la khalase le kopantsoeng → ka har'a autoclave → sehlahisoa se felileng

2. Khalase ea mohaho ea laminated e kobehileng

Ho hloekisa le ho omisa → ho kobeha ho chesang → ho hloekisa le ho omisa → ho kopanya → hloekisa → ka har'a autoclave → sehlahisoa se felileng

II.Lintlha tsa Khampani

1.Mabapi le rona

Litlhaloso tsa likarolo tsa Fangding Technology Co., Ltdke khoebo ea theknoloji e phahameng e thehiloeng ka Mphalane 2003, e sebakeng sa boikhathollo sa indasteri sa Taoluo, seterekeng sa Donggang, toropong ea Rizhao, e nkang sebaka sa lisekoere-mithara tse fetang 20,000, e nang le motse-moholo o ngolisitsoeng oa li-yuan tse limilione tse 100, o ikhethang ho nts'etsopele, ho etsa le ho etsa lihlahisoa. Ho rekisa thepa ea khalase ea laminated le lifilimi tsa interlayer, lihlahisoa tse kholo ke mochini oa khalase oa EVA oa laminated, Heat Soak Furnace, Smart PVB glass laminating line le lifilimi tsa EVA, TPU, SGP.

Hajoale, k'hamphani e na le laesense ea tlhahiso ea sekepe sa D1, D2, e fumane setifikeiti sa tsamaiso ea boleng ba ISO 9001, lihlahisoa li fumane setifikeiti sa European Union CE, setifikeiti sa Canada CSA le setifikeiti sa Jeremane sa TUV, se na le tumello e ikemetseng ea kantle ho naha le ka tatellano. e fane ka khoebo ea theknoloji e phahameng, khoebo ea litšephe ea profinse ea Shandong, mofuta o tummeng profinseng ea Shandong, le tse ling tse fetang tlotla tse 30.

'Marakeng oa machaba, lihlahisoa li romeloa linaheng tse ling ho ea Asia, Europe, Amerika le linaheng tse ling tse fetang 60 le libaka .E-ba le boikarabelo ho bareki le ho ntlafatsa hammoho le bona!E thehile motheo o tiileng oa likhoebo ho hlōlisana sethaleng sa machaba. .khamphani e hapile tšepo le thoriso ho tsoa ho bareki lefatšeng ka bophara ka lilemo.

2. Workshop & Shipment

Re etsa tlhahlobo e tiileng ea boleng pele re paka ke basebetsi ba litsebi le moenjiniere.

Mochine o tlatsitsoeng ka sephutheloana se tloaelehileng, o tla ts'oaroa ka thata ka har'a setshelo.

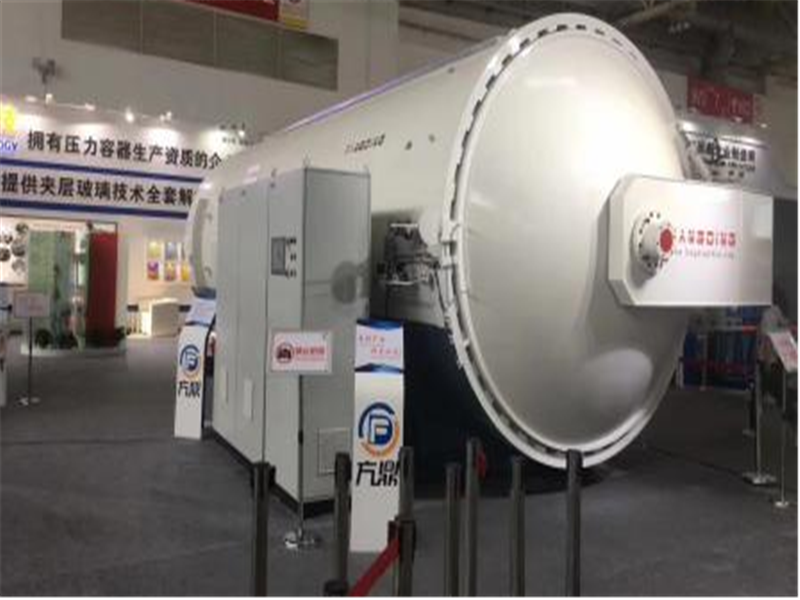

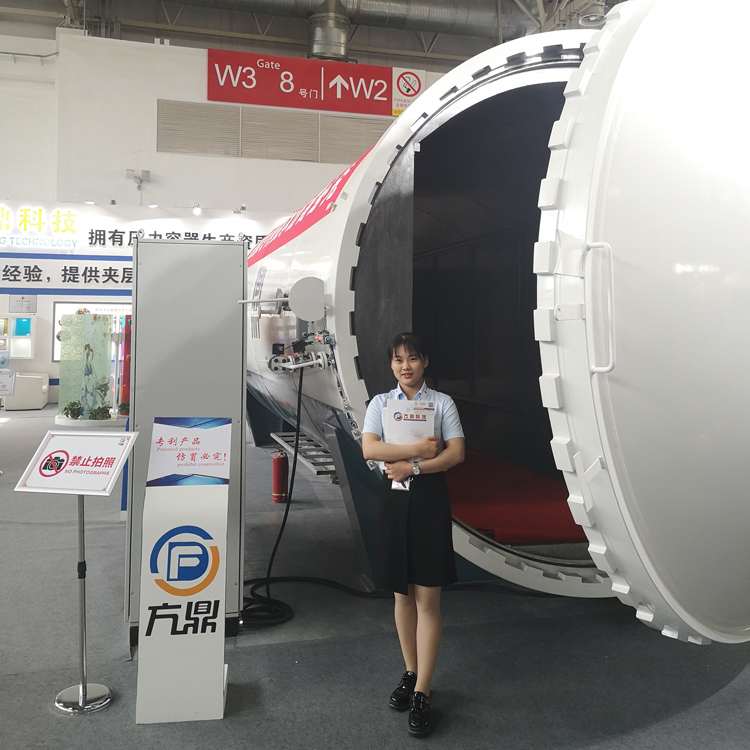

3.Pontšo

Re kenya letsoho lipontšong tse kholo tsa indasteri lapeng le kantle ho naha selemo se seng le se seng.Pontšo e hlakileng ea mochini, e u fang boiphihlelo bo hlakileng ka ho fetesisa!

III.Melemo

Re na le lefapha la litsebi tsa R&D, 'me baenjiniere ba rona ba na le lilemo tse ngata tsa boiphihlelo bo sebetsang le botekgeniki.Ho tloha mochining oa ho roala likhalase, sistimi ea laminating, mochini oa khatiso oa pele ho ea ho autoclave, re lula re ntlafatsa le ho nchafatsa, re hahamalla bokhabane, 'me re ikemiselitse ho fana ka mmaraka ka lihlahisoa tse ntle.

1. Ho amohela theknoloji e ncha ea ho futhumatsa, sesebelisoa sa ho futhumatsa se pota-potiloe ke mahlakoreng a mane, moralo o matla oa potoloho ea moea, ho finyella tekanyo ea mocheso ho autoclave, ho netefatsa boleng ba sehlahisoa, ho boloka matla le ho ntlafatsa katleho ea tlhahiso.

2. Sesepa sa ho ama, PLC le lisebelisoa tse ling tsa motlakase li na le lihlahisoa tsa machaba tse kang Siemens, Korea Boroa LS, joalo-joalo, ka ho rekota pampiri le mesebetsi ea polokelo ea data, ho hlahloba nako ea sebele ea mocheso le khatello ea khatello ho autoclave.Mocheso le khatello e nang le ts'ebetso ea ho laola li-interlock, matšeliso a mocheso a itekanetseng, matšeliso a khatello, ho netefatsa khatello le botsitso ba mocheso.

3. Theknoloji e ikhethang ea ho pholisa ea limaraka tse phahameng, tse bohareng le tse tlaase li ka fetola lebelo la ho pholisa ho latela litlhoko tsa bareki kapa lihlahisoa ho netefatsa chai.Joalo ka sehatsetsi se seholo, mochini o futhumatsang mocheso o fin o na le sebaka se seholo sa ho qhala mocheso le bokhoni bo phahameng ba phapanyetsano ea mocheso.

4. Software ea sesebelisoa e ka hlokomela phapanyetsano ea data, tlhahiso le polokelo.Letsetsa ho feta 40 disete tsa tshebetso parameters.Ka alamo ea phoso le mesebetsi e meng.

5. Sebelisa lisebelisoa tsa aluminium silicate tse nang le 80mm tse sireletsang tikoloho, ts'ebetso e phahameng ea mocheso oa mocheso le ho fokotsa tšebeliso ea matla.

6. Mehala eohle e amohela mokhoa oa ho roala ka ntle, o thibelang ka katleho mathata a botsofali a bakoang ke mocheso o feteletseng ka sebōping, o lelefatsa bophelo ba mohala, 'me o thusa ho boloka thepa le ho ntlafatsa.

7. Khampani e na le qualification ea tlhahiso ea sekepe sa khatello, 'me welding e sebelisa setsebi se seholo se nang le setifikeiti.Pele e tloha fekthering, e hlahlojoa ka thata ho latela maemo a tlhahlobo ea sekepe sa khatello.

8. Khampani e na le lefapha le ikemetseng la lipatlisiso le nts'etsopele, sehlopha sa kamohelo, ho tloha mohloling ho ea ho taolo ea boleng ba lintlha ka 'ngoe, boleng ba bohlale.

LBH

P: Na u moetsikapa k'hamphani ea khoebo?

A: Ke rona moetsi.Fektheri e akaretsa sebaka se fetang lisekoere-mithara tse 20,000 'me e ikemela e hlahisa mela ea tlhahiso ea khalase ea laminated, haholo-holo li-autoclaves.Re ba bang ba bahlahisi ba seng bakae ba malapeng ba nang le qualification ea ho hlahisa likepe tsa khatello.

P: Na u amohela boholo bo hlophisitsoeng?

A: E, re etsa joalo.Re na le setsebi sa theknoloji ea R&D le sehlopha sa meralo se nang le boiphihlelo bo fetang lilemo tse 30.Re tla u etsetsa moralo o loketseng ka ho fetisisa ho latela litlhoko tsa hau.

P: Ho nka nako e kae ho phethela aho sebetsapotoloho?

A: E khethoa ke sekhahla sa ho roala le lintlha tsa sehlahisoa.Hangata ho nka lihora tse 4-6.

P: Ho thoe'ng ka tekanyo ea automation ea mohala oa tlhahiso?

A: Re hlophisitse mela ea tlhahiso ea othomathike ka botlalo le ea semi-automatic, bareki ba ka khetha ho latela tekanyetso ea bona le sebaka sa bona sa marang-rang.

Q: Haeba moenjiniere oa hau a fumaneha mose ho maoatle ho kenyasebakeng seo?

A: E, baenjiniere ba rona ba nang le phihlelo ba tla tla fekthering ea hau ho kenya le ho laela mohala oa tlhahiso, le ho u ruta phihlelo ea tlhahiso le tsebo ea ho sebetsa.

P: Lipehelo tsa hau tsa tefo ke life?

A: 30% ea chelete eohle e lefshoa ke TT, 65% e lefshoa pele ho pepa, 'me 5% e setseng e lefshoa nakong ea ho kenya le ho laela.

P: Ho thoe'ng ka tšebeletso ea hau ea morao-rao?

1. Lihora tse 24 inthaneteng, rarolla mathata a hau ka nako efe kapa efe.

2. Tiisetso ke selemo se le seng mme tlhokomelo ke ea bophelo bohle.